Types of Ceramic Printing?

1. Screen Printing

- Traditional method using a mesh stencil and ceramic inks.

- Best for large runs with simple or repeat patterns.

- Durable and used often for tile manufacturing.

2. Lithographic Transfers (Decal Printing)

- Designs are printed on special decal paper using ceramic inks.

- Used for onglaze, underglaze, or in-glaze decoration.

- Can be applied manually or with machines.

3. Digital Ceramic Printing

- Inkjet printers with ceramic pigment inks.

- Ideal for custom or short-run items.

- High resolution and full-color images possible.

- Used for tiles, mugs, plates, etc.

4. Sublimation Printing (for coated ceramics)

- Transfers images using heat and pressure.

- Only works on ceramics with a polymer coating.

- Not permanent unless protected with coating; mainly for

decorative mugs and photo tiles.

What are Ceramic Transfers?

Ceramic transfers (also called ceramic decals) are specially printed images or patterns designed to be transferred onto ceramic surfaces and permanently fused through firing. They're essential in decorative ceramics for applying complex, multicolored designs quickly and consistently. These designs are applied to ceramics like tiles, plates, mugs, or pottery, and then fired in a kiln to bond the design to the surface.

Components of a Ceramic Transfer

- Special water-release paper or heat-release paper.

- Made with ceramic pigments and sometimes metallics like gold or silver.

- A thin plastic film that holds the design together during transfer.

- Water-soluble adhesive that lets the transfer slide off easily.

Digital Printing

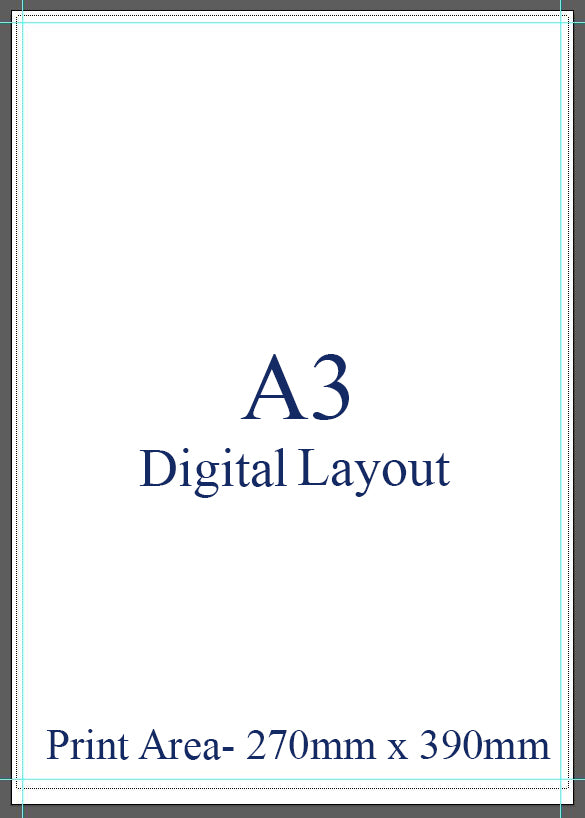

Digital Printing is a way of printing Ceramic Transfers onto waterslide paper. We would print your designs onto an A3 sheet. (each sheet is £12) So depending on how big your designs are, this could be quite a costly way of printing, however the positive is that you can just order one sheet at a time- This way of printing is a fairly quick turn around (within a couple of weeks)

The downside to printing digitally is we get a lack of vibrancy with the colours, and each sheet we print the colour can change quite a bit, so there's the lack of consistency. We normally use this printing for one off items or samples to see how the design looks. Digitally printing is a good way to get smaller quantities printed fairly quickly.

Ordering could not be simpler.

Complete the enquiry form below and we will be in contact to help you.

Printed on an area of A3 (28 x 40 cm)

Delivery within 5 working days from receipt of your artwork.

Our minimum order is as little as one sheet without any surcharges.

We can offer decorating and firing if required.

Print Charges

1 x Sheet = £12.00 exc VAT and postage

Artwork or Design

- We can only accept the following formats – PDF, EPS, PSD, JPEG, TIFF

- Artwork needs to be a minimum of 300dpi for the best results

- Print area is A3 (28 x 40), please allow for a small border around the edge.

- You can add as many transfers as required within the print area.

Matching your design or artwork.

The following colours cannot be achieved with digital printing, however we can offer silk screen as an alternative if the colours shown below are required.

- white

- gold

- metallic

- colours

Decorating

- If you’re decorating yourself, follow the instructions below for the best results.

- Warm the ware first to 20-30 degrees C

- Cut around your images and immerse in water for 30-40 seconds.

- Slide the transfer from the backing paper.

- Apply to your ware

- Ensure there are no air bubbles or creases.

- Allow time for the transfer to dry before firing.

- Once fired your transfer will be set into the glaze of your whiteware and will not fade like some other printing methods and will be dishwasher and microwave safe providing the ware is.

Firing Temperature

Firing temperatures can vary on the ware you are using, see

below for more information.

- Earthenware 800-820 degrees C

- China Body (Thick) 820-840 degrees C

- Bone China (Thin) 820-840 degrees C

- Porcelain 840-890 degrees C

- Stoneware 840-890 degrees C

We have our own team of lithographers and gilders who can decorate and fire, alternatively, we can provide the transfers for you to decorate yourself.

Silkscreen Printing

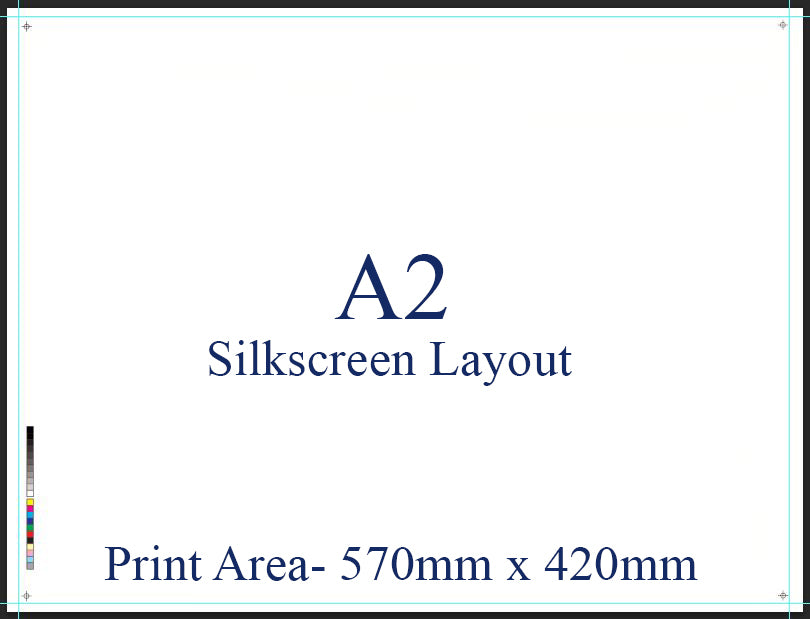

We have years of experience in silk screen printing and we can produce in single colour, multi colour, half tone and four colour process.

Order Quantity

Minimum order quantity can be as small as 100 transfers with no maximum limit.

Print Charges

- The price can vary based on the size, quantity and the amount of colours in your artwork. Therefore, we would ask that you forward your image to us in the following formats .jpg, .tiff, .psd, .pdf, or .eps to our email address at steven.swindell@finsburychina.co.uk, in order that we can give you an accurate quote.

- We can colour match to pantone references or your own specification. White, gold and silver including metallic colours can be achieved with silk screen.

- Your design will be printed on waterslide paper and can be decorated onto glazed ceramic ware.

- Prints can be sold separately or we can decorate and fire them here as a package price.

- We can alter the size of your image to your requirements.

- To enquire about silk screen printing simply use the below contact form and we will be in touch to help you with your enquiry.

Silkscreen printing of water slide transfers for fine bone china mugs is a traditional and highly skilled process. It involves multiple precise steps to ensure delicate, intricate designs are permanently and beautifully fused onto the ceramic surface. Here’s a breakdown of the process:

1. Design Preparation

- A graphic designer creates a detailed artwork, often featuring florals, crests, or intricate patterns.

- The design is separated into individual color layers (one screen per color).

- Each color layer is turned into a positive film to be used in screen exposure.

2. Screen Preparation

- A mesh screen is coated with photo-sensitive emulsion.

- The positive film (one for each color) is placed on the screen and exposed to light.

- Light hardens the emulsion except where the image blocks it, leaving a stencil of the design.

3. Silkscreen Printing the Transfer

- Special ceramic inks (oxide-based) are used. These withstand kiln temperatures and fuse with the glaze.

- The screen is placed over water-slide decal paper, a special paper with a water-soluble layer.

- Ink is pushed through the screen onto the paper using a squeegee.

- The process is repeated layer by layer for each color, with careful registration.

4. Drying & Finishing the Transfer

- After printing, the sheets are air- or heat dried.

- A covercoat is applied—this is a protective, transparent layer that keeps the ink intact during handling and soaking.

We make things that work better and last longer. Our products solve real problems with clean design and honest materials.

Compilation Layout Printing

A compilation layout is simply a 4 colour layout (cyan, magenta, yellow and black) where we could put your design on along with our other customers, and you'd share the layout(and the cost). So you would just be paying for the percentage of the layout that your design takes up.

This would still mean you would have to pay for the x100 transfers of each design.This would mean that we are stuck with just 4 colours to recreate all of your colours in your designs(yellow + cyan for green ect), which means the colour will not be exact to your designs.

Spot Colour Layout Printing

This is the "proper" way of printing and would get the best results. We would print your own layout (A2 piece of paper) and the minimum sheet run is x100. This way we would print your own colours (Pantone Matched) This would mean that the colours would be a near exact match to your artwork.

The downside to this is that it is costly. For the printing alone you could be looking at thousands of pounds, for alot of transfers that you may not use.This way of printing we would normally do for large companies who order thousands of pieces of ware a month.

For both spot colour and silkscreen printing, we are happy for you to pay for the transfers upfront, and then just call off whatever quantity of teapots/cups you wanted. Both of these take a minimum of 4 weeks to print.